Recommendation Info About How Much Torque Is 40Nm

40nm Torque Atelieryuwa.ciao.jp

Understanding 40Nm of Torque

1. What Exactly Does Torque Mean?

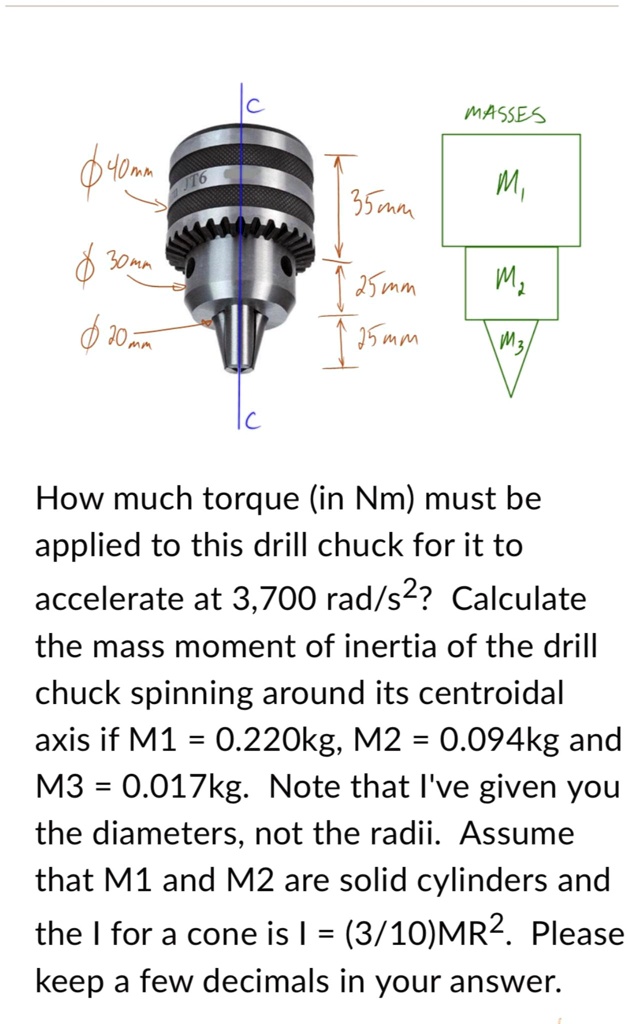

Ever wondered what that "Nm" figure means when someone's talking about cars, power tools, or even bicycles? Well, it stands for Newton-meters, and it's a unit of torque. Simply put, torque is a twisting force that causes rotation. Think of it like this: it's what gets things spinning! 40Nm of torque, therefore, is a specific amount of that rotational oomph.

Imagine trying to loosen a really stubborn bolt. The force you apply to the wrench handle to turn it? That's torque in action. The longer the wrench handle, the more leverage you have, and the easier it is to generate the necessary torque. Similarly, a higher torque figure generally means more "twisting power" is available.

Torque is essential in many mechanical systems, from the engine of your car to the small motor in a food processor. Without it, things just wouldn't turn, and a lot of our gadgets and machines would be rendered useless. So, next time you hear someone mention torque, remember it's all about the twisting force.

It's easy to get torque confused with power (measured in horsepower or kilowatts). While they're related, they aren't the same. Think of torque as the initial "grunt" — the force that gets something moving. Power is how quickly that movement can be sustained. So, a high-torque engine might be great for towing a heavy load, while a high-power engine might be better for achieving high speeds.

40Nm in Everyday Life

2. Real-World Examples of 40Nm in Action

Okay, so 40Nm is a twisting force, but what does that actually feel like? Where do we encounter it in the real world? Let's consider some examples. This is where things get interesting because 40Nm, while not astronomical, is a respectable amount of rotational force.

Consider a power drill. Many cordless drills designed for general home improvement tasks, like assembling furniture or hanging pictures, will have a torque setting around 40Nm. This allows you to drive screws into wood without stripping the threads or damaging the material. It's enough grunt for most DIY projects.

Another example is a bicycle. While the torque required to pedal a bike varies depending on the gear and the incline, 40Nm represents a significant amount of force you'd be exerting on the pedals, particularly when climbing a hill. It would definitely make your legs burn! It's also a good amount of torque for tightening bolts on your bike to ensure things are secure.

Even some electric screwdrivers can output around 40Nm. These devices are great for quick and easy tasks like assembling flat-pack furniture and other light-duty jobs around the house. It's enough to drive screws efficiently without requiring significant manual effort. So you aren't left with sore wrists!

Digital Torque Wrench 40nm200nm AA Battery Tools USB Type

Is 40Nm a Lot? Perspective is Key

3. Putting 40Nm into Context

Whether 40Nm is "a lot" depends entirely on the context. For a tiny electric toothbrush motor, 40Nm would be utterly insane! But for a car engine, it's a relatively small number. Let's look at some comparisons to get a better feel for its relative strength. Comparing it is a great way to get a feel for its power.

Think about a small motorcycle engine. Many scooters or small motorcycles might produce peak torque figures in the range of 10-20 Nm. A larger motorcycle, such as a sportbike, could easily generate over 100 Nm of torque. So, 40Nm falls somewhere in the middle — enough to be useful, but not enough to set any land speed records.

Compared to the torque produced by car engines, 40Nm is considered low. Even a small, fuel-efficient car will usually generate significantly more torque than that. High-performance cars can produce hundreds of Newton-meters of torque, allowing for rapid acceleration. So the scale of torque really varies quite a lot!

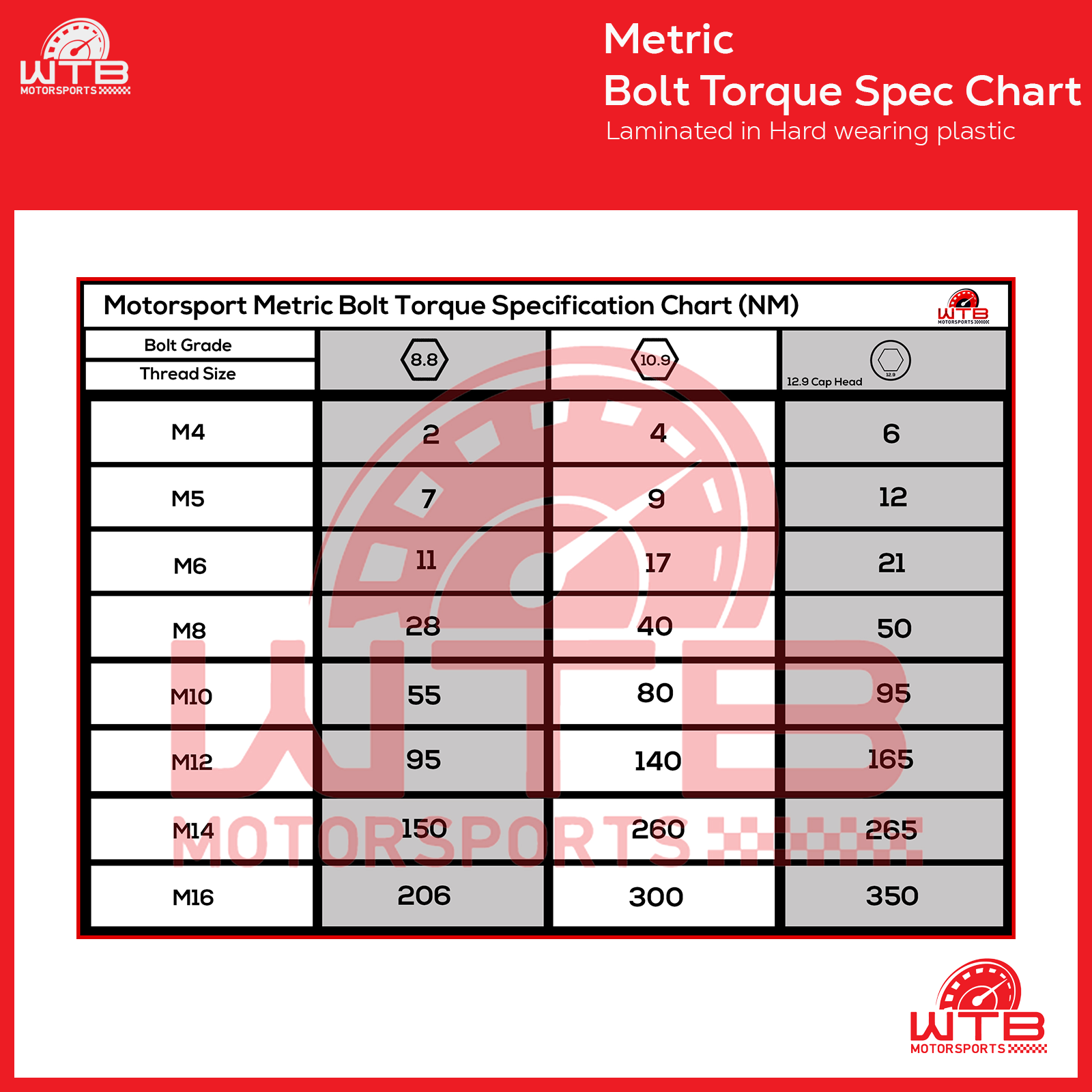

For smaller tools like manual screwdrivers or wrenches, 40Nm would represent a considerable force. It's the kind of torque you'd use when tightening bolts on a car suspension or a large piece of machinery. So while a small amount relative to a motor, it is considerable force.

Metric Bolt Torque Chart Charts Pdf Bolting Tools Industrial

How to Measure Torque

4. Tools and Techniques for Measuring Rotational Force

So, how do you actually measure torque? Well, there are specialized tools designed for this purpose. The most common is a torque wrench. A torque wrench allows you to apply a specific amount of torque to a fastener, ensuring it's tightened to the correct specification. This is crucial in many applications, as over-tightening can damage parts, while under-tightening can lead to loosening and failure.

Torque wrenches come in various types, including click-type, beam-type, and digital torque wrenches. Click-type wrenches are the most common. You set the desired torque value, and when you reach that value, the wrench "clicks," indicating that you should stop applying force. Beam-type wrenches use a pointer and a scale to indicate the torque being applied, while digital wrenches provide a precise digital readout.

For measuring the torque produced by a motor or engine, more sophisticated equipment is required, such as a dynamometer (or "dyno" for short). A dyno measures the torque and power output of a rotating machine. It can be used to test the performance of engines, motors, and other rotating devices, helping engineers optimize their designs.

Another useful concept is using a simple lever arm. By applying a known force at a measured distance from a pivot point, you can calculate the torque. This is the basic principle behind how wrenches work, and it can be a useful way to estimate torque in certain situations. Just remember to be precise with your measurements!

40nm Torque Atelieryuwa.ciao.jp

Using 40Nm Safely

5. Preventing Damage and Injury When Applying Torque

Working with tools that generate or apply torque can be dangerous if you're not careful. Always use the correct tool for the job and follow manufacturer's instructions. Don't try to over-tighten bolts, as this can damage the threads or even break the fastener. Always wear appropriate safety gear, such as gloves and eye protection, to protect yourself from injury.

When using a torque wrench, make sure it's properly calibrated. A poorly calibrated torque wrench can provide inaccurate readings, leading to over- or under-tightening. Regularly check the calibration of your torque wrench to ensure it's providing accurate results. This is especially important for critical applications where precise torque is essential.

Avoid using cheater bars or other makeshift extensions on wrenches to increase leverage. This can significantly increase the torque being applied, potentially leading to damage or injury. It's better to use a longer wrench designed for the task, or to use a specialized tool designed for applying high torque.

Always be aware of your surroundings when working with tools. Make sure you have enough space to maneuver and that you're not in danger of hitting anything. Use proper lifting techniques to avoid strain and injury. And if you're unsure about anything, consult a qualified professional.

Ignition Timing After Peak Torque At Lisa Marybeth Blog

FAQ

6. Q

A: Not necessarily! It depends on the application. For some things, like driving screws into drywall, too much torque will just strip the screw head. Other applications, like tightening lug nuts on a car wheel, require a specific torque to ensure safety. The key is to use the right amount of torque for the job.

7. Q

A: Absolutely! Common conversions include foot-pounds (ft-lbs) and inch-pounds (in-lbs). You can easily find online converters to switch between these units. Keep in mind that different units are often used in different industries, so it's good to be familiar with a few of them.

8. Q

A: Overtightening can stretch the bolt beyond its yield strength, weakening it. It can also damage the threads in the bolt or the material it's being tightened into. In extreme cases, it can even cause the bolt to snap. So, be careful out there!